The Basics of Smoke Control Made Simple

Do you struggle to understand smoke control for fire alarm systems? No need to stress out as you are not alone. Let's break it down so it is easier to digest.

Fire alarm systems are essential for the activation and operation of smoke control systems. Fire alarm systems can detect the presence of fire and smoke, alert the occupants and the fire department, and initiate the appropriate smoke control actions. Fire alarm systems can also monitor the status and performance of smoke control systems and provide feedback and control signals to the building management system. Fire alarm systems should be listed, compatible and integrated with the smoke control systems to ensure coordinated and effective response to fire emergencies.

Smoke control systems are complex and require careful design, installation, and maintenance. Smoke control systems should be based on a thorough analysis of the fire hazards, the building characteristics, the occupant needs, and the fire department operations. This approach is referred to as a smoke control report or rational analysis and is required to be completed by a registered fire protection engineer (FPE) per the International Building Code 2021 Section 909.4. The rational analysis or smoke control report will cover which type of smoke control system will be employed (passive vs. mechanical), which smoke control method will be utilized (pressure, exhaust, or air flow), construction methods, sequence of operation and inspection and testing procedures. There are other items covered within the report such as but not limited to stack effect, temperature effect of fire, wind effect, climate and duration of operation.

What Codes and Standards Dictate Smoke Control Systems?

- 2021 International Building Code (IBC) Chapter 9: Fire Protection and Life Safety Systems

- ASHRAE Handbook of Smoke Control Engineering

- NFPA 92: Standard for Smoke Control Systems

- NFPA 101: Life Safety Code

- NFPA 72: National Fire Alarm and Signaling Code

Where are Smoke Control Systems Required per Code?

- Atriums (three stories or more) within covered malls - IBC 2021 Section 402.7.2.

- High-Rise Buildings - IBC 2021 Section 403.4.7.

- Atriums (three stories or more) - IBC 2021 Section 404.5.

- Underground Buildings - IBC 2021 Section 405.5.

- Mechanical Access Enclosed Parking Garage -IBC 2021 Section 406.6.4.2.

- Windowless Buildings Group I-3 - IBC 2021 Section 408.9

- Large Stages (Greater than 1,000sq' in Area or 50' in Height) - IBC 2021 Section 410.2.7.

Smoke control systems can be classified into two main types: passive and mechanical.

Passive smoke control systems rely on the buoyancy and pressure differences of smoke and air to create ventilation openings that allow smoke to escape and fresh air to enter. Examples of natural smoke control systems are automatic opening vents (AOVs), atrium exhausts, opposed airflow, and smoke reservoirs.

- Openings are protected by automatic closing equipment or devices.

- Fire Dampers and Combination Fire Smoke Dampers

- Fire Rated Doors with Magnetic Hold Open Devices (Door Holders)

- Activation - Consult the Approved Rational Analysis / Smoke Control Report.

- Smoke Detectors / Heat Detectors located at fire rated doors and combination fire smoke dampers.

- Duct Smoke Detectors located at HVAC units for shutdown and combination fire smoke dampers.

- Verification NOT required.

- Positive status of fan shutdown, door closure or damper activation is not required per IBC 2021 Section 909.12.1. Consult the rational analysis as it may supersede this code section.

- Wiring

- In addition to the requirements of NFPA 70, all wiring regardless of voltage shall be fully enclosed within a continuous raceway.

- Pressurization Method - IBC 2021 Section 909.6. This approach utilizes pressure differences across smoke barriers to maintain a tenable environment zones adjacent to the smoke control zone of origin.

- Per IBC 2021 section 909.6.1, the minimum pressure across the smoke barriers is 0.05" water gauge.

- The maximum pressure differential is dependent upon the opening force of exit doors. Per IBC 2021 section 1010.1.3 #2, the door shall not require more than 30 pounds of force to set in motion and 15 pounds to fully open.

- Required to have complete automatic control 2021 IBC section 909.12.3.1.

- In addition to the requirements of NFPA 70, all wiring regardless of voltage shall be fully enclosed within a continuous raceway.

|

| Smoke Control Pressurization Method Detail |

|

| Smoke Control Stairwell Pressurization |

- Exhaust Method - IBC 2021 Section 909.8. Where approved by the AHJ, the exhaust method may be utilized in large areas such as atriums or malls. Large smoke exhaust fans are utilized to evacuate smoke from the area. Makeup air (MAU) fans, automatic windows or doors may be used to replace air removed from the space by process of the smoke exhaust fan. When the smoke control exhaust method is utilized, the system must keep the smoke layer at least six feet above the highest level meant for egress within the smoke zone. Smoke Control Systems utilizing the exhaust method shall be designed in accordance with NFPA 92.

- Required to have complete automatic control 2021 IBC section 909.12.3.1.

- In addition to the requirements of NFPA 70, all wiring regardless of voltage shall be fully enclosed within a continuous raceway.

|

| Smoke Control Exhaust Method Detail |

|

| Smoke Control Exhaust Method Atrium |

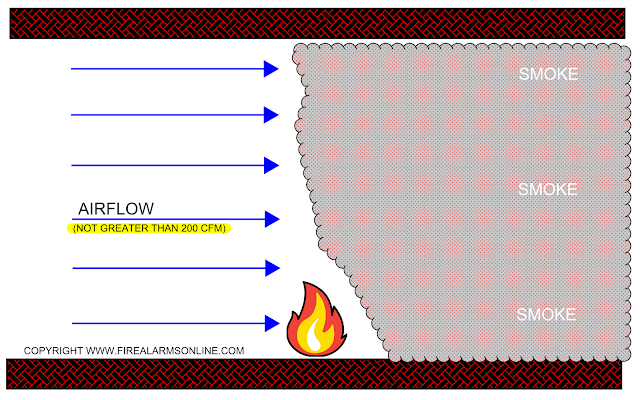

- Air Flow Method - IBC 2021 Section 909.7. Where approved by the AHJ, the air low method is used for facilities with smoke migration through openings that are in the permanently open position. Airflow shall be directed to limit smoke migration from the zone. Airflow shall not exceed 200 feet per minute. Smoke Control Systems utilizing the air flow method shall be designed in accordance with NFPA 92.

- This method shall not be employed where either the quantity of air or the velocity of the airflow will adversely affect other portions of the smoke control system, intensify the fire, disrupt smoke plume dynamics or interfere with exiting. Airflow towards the fire shall not exceed 200 feet per minute. Where the calculated airflow exceeds this limit, the airflow method shall NOT be used. 909.7.1.

- Required to have complete automatic control 2021 IBC section 909.12.3.1.

- In addition to the requirements of NFPA 70, all wiring regardless of voltage shall be fully enclosed within a continuous raceway.

|

| Smoke Control Airflow Method Detail |

Duration of Operation

What is Verification or Positive Status?

|

| Fire Smoke Damper Status Monitoring Open Detail |

There is more to smoke control verification.

- Where verification of individual components tested through the preprogrammed weekly testing sequence will interfere with, and produce unwanted effects to, normal building operation, such individual components are permitted to be bypassed from the preprogrammed weekly testing, when approved by the AHJ and in accordance with BOTH of the following:

- Where the operation of components is bypassed from the preprogrammed weekly test, presence of power downstream of all disconnects shall be verified weakly by a listed control unit.

- Testing of all components bypassed from the preprogrammed weekly test shall be in accordance with section 909.20.6 of the International Fire Code IFC.

|

| Example of a UL Listed Smoke Control Printer for Weekly Testing Reports |

Fire Fighter's Smoke Control Panel

Smoke Control Indication LEDs

- Fans, Dampers and Other Operating Equipment NORMAL status = WHITE

- Fans, Dampers and Other Operating Equipment OFF or CLOSED status = RED

- Fans, Dampers and Other Operating Equipment ON or OPEN status = GREEN

- Fans, Dampers and Other Operating Equipment FAULT status = AMBER/YELLOW

Smoke Control Switches

- ON-AUTO-OFF control over each individual piece of operating smoke control equipment that can be controlled from other sources within the building. This can include: stair pressure fans, smoke exhaust fans, supply fans, return fans, exhaust fans, elevator shaft fans, and other operating equipment used or intended for smoke control purposes.

- ON-AUTO-OFF control over individual dampers relating to smoke control and that are controlled from other sources within the building.

- ON-OFF or OPEN-CLOSED control over smoke control and other critical equipment associated with a fire or smoke emergency and that can only be controlled from the fire fighters smoke control panel.

- For complex systems (where approved), controls and indicators can be combined to control and indicate all components of a single smoke zone as a single unit. This allows for one switch to control multiple doors, dampers or fans within a single smoke zone. Example: Five dampers on the 10th floor that are all required to close upon smoke mode activation could be controlled and indicated on a single switch with LEDs on the 10th floor of the fire fighter's smoke control panel. 2021 IBC Section 909.16.2

Fire Fighter's Smoke Control Example

Smoke Control System Response Time

Power Requirements

- Standby Power Requirements per section 2702.2.17 of the 2021 IBC states that standby power shall be required for smoke control systems per sections 404.7, 909.20.7.2, and 909.21.5.

- Per section 909.12.1 the smoke control system shall monitor for the presence of power downstream of all disconnects. This will require a monitor module as well as an isolation relay (PR-1 or MR-101) at each power source. Make sure to pay attention to DAMPERS. A lot of the systems today will have a light switch adjacent to the damper actuator for the purpose of dropping power to the unit for service. If this is the case, you will need a monitor module and relay at each of these locations. Pay attention to this when bidding a project as this could potential add quite a few more modules than you may have accounted for.

How are smoke control systems commissioned and tested?

- Per the 2021 IBC, Section 1705.19, Smoke Control Systems shall be tested by a special inspector.

- As defined by the 2021 IBC Definitions, a special inspector is a qualified person employed or retained by an approved agency and approved by the building official as having the competence necessary to inspect a particular type of construction requiring special inspection.

- Per the 2021 IBC, Section 1705.19.1, the Smoke Control Testing Procedure shall include:

- During erection of ductwork and prior to concealment for the purpose of leakage testing and recording of device and equipment locations. This includes but not limited to fans, dampers, smoke detectors, waterflow switches, and verification equipment as outlined above.

- Prior to occupancy and after sufficient completion for the purpose of pressure differential testing, air flow measurements and detection and control verification.

- Per 2021 IBC, Section 1705.19.2, approved agencies for smoke control testing shall have expertise in fire protection engineering, mechanical engineering, and certification in air balancing.

- Per 2021 IBC Section 909.18.8.3, A complete report of testing shall be prepared by the approved agency. The report shall include identification of all devices by manufacturer, nameplate data, design values, measured values, and identification tags. Your hope shall be reviewed by the responsible registered design professional and, when satisfied that the design intent has been achieved the responsible registered design professional shall sign seal and date the reporter.

- A copy of the final report shall be given to the fire code official along with an identical copy to be filed in an approved location at the facility. 2021 IBC 909.18.3.1.

- Charts drawings and other documents identifying and locating each component of the small control system as well as describing its proper function and maintenance requirements shall be maintained on file at the building and accompany the report required by section 909.18.8.3. Devices shall have an approved identifying tag on them consistent with the other required documentation and shall be dated indicating the last time they were successfully tested and by whom.

- 2021 IBC Section 909.19 states, buildings that are required by this code to employ a smoke control system shall not be issued a certificate of occupancy until such time that the AHJ determines the provisions of chapter 909 have been fully complied with and that the fire department has received ample instruction on the operation both automatic and manual operation of the smoke control system. In addition, a written maintenance program complying with the requirements of section 909.20.1 of the International Fire Code (IFC) has been submitted and approved by the AHJ.

Plan on at least three inspections to commission a smoke control system.

- Pre-Test the system. Just like a fire alarm system, the sequence and equipment must be ran through prior to calling out the AHJ. The pre-test shall be conducted once all of the power is present, doors are installed, and all fire alarm/smoke control components are in place and programmed per the rational analysis, sequence of operations and approved documentation. Verify all indicators on the fire fighter's smoke control panel as well as manual and automatic operation.

- Test with the third-party fire protection firm. Please note this can be the same firm that performed the rational analysis pending they have sufficient training and expertise in testing and commissioning smoke control systems. Depending on the individual conducting the third-party test you may have different requirements. However, you should still run through everything you tested during the pre-test as well as the pre-programmed weekly self-test. At the end of this test, the third party testing firm will issue a report per section 909.18.8.3 and give it to the Fire Code Official.

- Final inspection with the AHJ / Fire Code Official. Once the third-party testing firm has issued their report, the AHJ will want to run through a final test. It is up to the AHJ on what will be tested. In my experience, some AHJs will trust the third-party testing firm and perform minimal testing to satisfy their needs. However, some AHJs will want to run through a complete test of all components. Keep this in mind when bidding projects as these tests can take quite a while depending on their complexity.

.jpg)