Wood frame construction is a prevalent building method due to its cost-effectiveness, sustainability, and ease of assembly. However, wood is inherently combustible, making fire safety a critical concern during the construction phase. Furthermore, traditional fire protection systems such as automatic fire sprinklers and fire walls are not yet existent during the construction phase. One of the most effective ways to mitigate fire risks during construction is the implementation of a temporary fire alarm system.

This article dives deep into why fire alarm systems are indispensable during wood frame construction, with a focus on technical details, compliance requirements, and how to integrate them effectively.- 4,440 annual average fires in structures under construction, renovation, or being demolished.

- $370 million annual average cost of property damage in structures under construction, renovation or being demolished.

- 59 annual average civilian injuries in structures under construction, renovation, ore being demolished.

- 5 annual average civilian deaths in structures under construction, renovation or being demolished.

- Cooking equipment was the leading cause of fires on construction sites.

- Fires in structures under construction were most common in the afternoon and evening; however, fires that occurred between midnight and 6:00 AM accounted for just over 51% of the direct property damage.

- 76% of the fires and structures under construction involved residential properties and accounted for the largest shares of deaths injuries and direct property damage.

Why Fire Alarm Systems for Wood Frame Construction are Crucial

1. Increased Fire Risks During Construction

According to NFPA, the leading causes of fires in unfinished wood frame construction sites are as follows:

Temporary heating devices and on-site fuel storage compound the hazard.

2. Safety of Personnel and Construction Crews

Construction sites are dynamic environments with numerous workers, increasing the need for rapid fire detection and response to ensure safety. A majority of construction workers will be wearing some form of hearing protection during the construction phase of these projects. The current standard emergency air horns located throughout these wood frame construction sites would be deemed useless as hearing protection and electric/gas powered tools make it difficult if not nearly impossible to hear the alert in the event of a fire emergency.

3. Compliance with Codes and Standards

Most jurisdictions mandate temporary fire protection measures during wood frame construction.

The 2021 International Building Code (IBC), the 2021 International Fire Code (IFC) and National Fire Protection Association (NFPA) standards, particularly 2022 NFPA 241, emphasize the need for fire safety during wood frame construction, including fire alarm systems.

- Fire Protection

- Housekeeping

- On-Site Security

- Fire Protection Systems

- Pre-Fire Plan

- Communication Systems

- Documents for Training, Testing and Drills

- Special Hazards

- On-Site Fire Brigade or Emergency Response Personnel

- "In accordance with the Fire Prevention Program"

- "Evaluated based on the hazard and the scope of the temporary measures"

4. Property Protection and Investment

Fires during construction can result in catastrophic financial losses. Early fire detection systems in wood frame construction minimize damage and ensures the project stays on schedule. Between the years 2017 and 2021, the leading cause of fires in wood frame construction that lead to the most property damage was electrical distribution and lighting equipment with intentional arson coming in a close second.

Types of Fire Alarm Systems for Wood Frame Construction Sites

1. Wireless Fire Alarm Systems

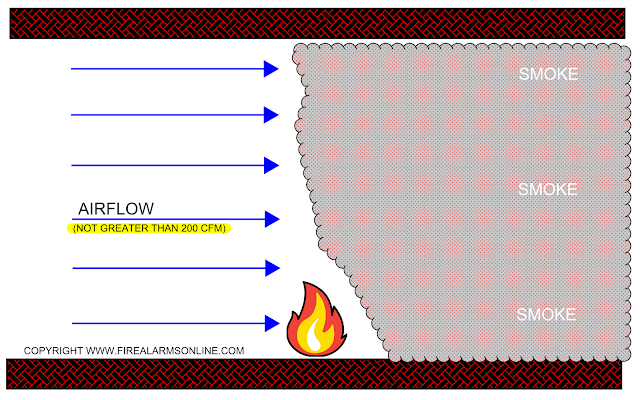

Wireless systems are ideal for construction sites as they are portable and easy to install. They use radio frequency communication through a mesh network to detect smoke, heat, and initiate alarms via contact closure from waterflow switches, tamper switches, or other systems. These wireless inputs can be programmed to trigger output relays or wireless notification appliances. With the use of wireless horns in conjunction with strobes lights, we can dramatically cut down on the evacuation time of fires in wood frame construction sites.

Advantages of temporary wireless fire alarm systems:

Quick installation. Without the need for extensive wiring and the ability to install and relocate equipment in minutes makes this option very favorable.

Flexibility to adapt as the site evolves. Keep in mind as the wood frame construction site progresses, there will be a need to relocate detectors and notification appliances.

- Wireless control unit with SIM card for monitoring. (Can support up to 999 fully supervised wireless units)

- Wireless call points with sounder strobe (call point can be removed)

- Wireless dust resistant smoke detectors

- Wireless heat detectors

- Wireless interface module (connection to other systems, sprinkler switches, etc.)

- Wireless link unit to extend the wireless range in large applications

- Equipment has a battery life span of three years when used under normal circumstances.

- All equipment has built in tamper switches on the backside of the back box.

- Call point unit has a medical alert function as well as the fire alarm activation.

- Call points are suitable for indoor or outdoor installation under IP55 conditions.

- Mesh network with approximately 200 feet of coverage per wireless unit.

|

| Pictured from left to right: WES3 Wireless Dust Resistant Smoke Detector, WES3 Wireless Control Unit, WES3 Wireless Call Point with Sounder Strobe and Medical Alert |

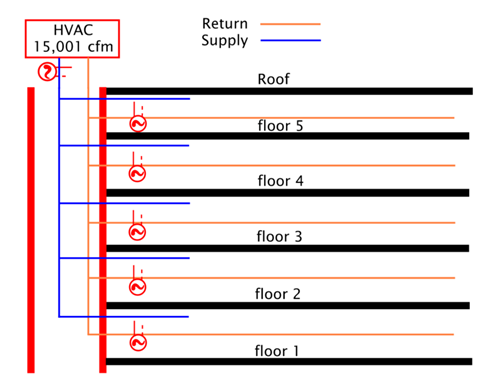

2. Hardwired Fire Alarm Systems

Temporary hardwired fire alarm systems involve traditional wiring and are typically used when parts of the structure are already enclosed. They provide reliable connectivity but are less flexible. Hardwired systems are also more costly and time consuming to install. Not to mention the wire used for the temporary system will be demolished and discarded once the permanent solution is installed.

Example Configuration of a Hardwired Temporary Fire Alarm System:

- A headend Fire Alarm Control Panel (FACP) "Keep in mind this approach will require a dedicated 120 Volt circuit as well as battery backup. We dedicated circuit may not be available depending on the phase of construction."

- DACT for communication to the Central Station

- Smoke detectors placed on exposed wood and near temporary electrical setups.

- Heat detectors installed in high-risk areas like hot work zones.

- Protectowire linear heat detection cable

- Pull Boxes at exits or other strategic locations

- Connection to other systems or sprinkler switches

- Horns and or strobes.

1. Placement of Detectors or Linear Heat Detection Cable

Smoke and or heat detectors should cover all high-risk areas such as:

- Near temporary power supplies and generators.

- Close to welding and cutting stations.

- Inside storage areas containing flammable materials.

Alarms should integrate with temporary sprinkler systems or fire suppression tools.

Link alarms to construction site monitoring systems for real-time alerts.

3. Testing and Maintenance

Conduct weekly tests of fire alarm systems during construction.

Replace batteries and address faults promptly.

4. Compliance with NFPA 241 Standards

Conclusion

The use of fire alarm systems during wood frame construction is not only a compliance necessity but a practical strategy to ensure safety and minimize risks. By integrating modern technologies, adhering to regulatory standards, and prioritizing maintenance, construction teams can mitigate fire hazards effectively. These systems protect workers, investments, and the overall progress of the project, making them indispensable tools in the construction industry.