NFPA 72 2016 Chapter 21 - Emergency Control Function Interfaces

The following information contains the changes, updates and additions to Emergency Control Function Interfaces found in Chapter 21 of the NFPA 72 2016 edition. Remember if you see a * make sure to consult the Annex A for additional information.

All information highlighted in this light blue color is NEW to the 2016 edition of NFPA 72.

- 21.1.1 The Requirements of Chapters 7, 10, 17, 18, 23, 24, and 26 shall apply, unless otherwise noted in this chapter.

- 21.1.3 The requirements of this chapter shall not apply to Chapter 29 unless otherwise stated.

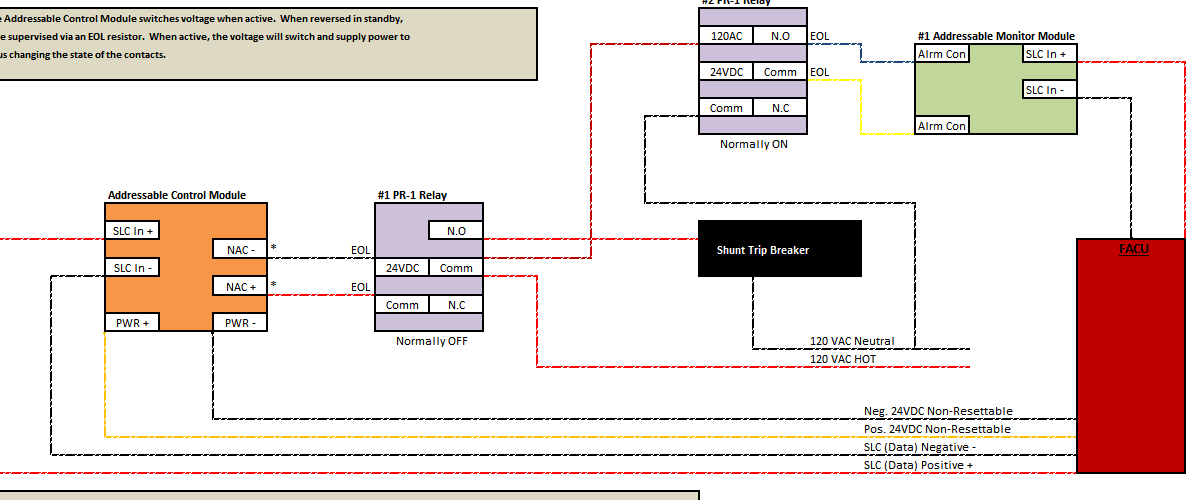

- 21.2.6 The installation wiring between the fire alarm control unit and the emergency control function interface device shall be Class A, Class B, Class D, Class N, or Class X in accordance with NFPA 72 Chapter 12 Circuit Pathways.

The following pertains to Elevator Phase 1 Recall

- 21.3* Elevator Phase 1 Emergency Recall Operation

- 21.3.1 All fire alarms initiating devices used to initiate elevator phase 1 emergency recall operation shall be connected to the required building fire alarm system.

- 21.3.2* In facilities without a required building fire alarm system, fire alarm initiating devices used to initiate elevator phase 1 emergency recall operation shall be connected to either a non-required building fire alarm system or a dedicated function fire alarm control unit that shall be designated as "elevator recall control and supervisory control unit," permanently identified on the dedicated function fire alarm control unit and on the record drawings.

The following is a California State Amendment.

- 21.3.6 Smoke detectors shall not be installed in un-sprinklered elevator hoistways unless they are installed to activate the elevator hoistway smoke relief equipment or where required by Chapter 30 by the California Building Code (CBC).

CBC: 3005.4.1 Automatic sprinkler system. Automatic sprinklers shall not be required to be installed in the elevator hoistway, elevator machine room, elevator machinery space, elevator control space, or elevator control room where the following are met. NOTE: All 6 of the following conditions must be met.

- Approved smoke detectors shall be installed in the elevator hoistway, elevator machine room, elevator machinery spaces, elevator control spaces, or elevator control rooms and connected to the building fire alarm system in accordance with Section 907.

- Activation of any smoke detector located in the elevator hoistway, elevator machine room, elevator machinery spaces, elevator control spaces, or elevator control room shall cause the actuation of the building fire alarm notification appliances in accordance with section 907.

- Activation of any smoke detector located in the elevator hoistway, elevator machine room, elevator machinery spaces, elevator control spaces, or elevator control room shall cause all elevators having equipment located in that elevator hoistway, elevator machine room, elevator machinery spaces, elevator control spaces, or elevator control room to recall nonstop to the appropriate floor in accordance with CCR Titile 8, Division 1, Chapter 4, Subchapter 6, Elevator Safety Order.

- The elevator machine room, elevator machinery spaces, elevator control spaces, or elevator control room shall be enclosed with fire barriers constructed in accordance with Section 707 or horizontal assemblies constructed with Section 712, or both. The fire-resistance rating shall not be less than the required rating of the hoistway enclosure served by the machinery. Openings in the fire barriers shall be protected with assemblies having a fire protection rating not less than that required for the hoistway enclosure doors. The exception to Section 3005.4 shall not apply.

- The building fire alarm system shall be monitored by an approved supervising station in accordance with Section 907.

- An approved sign shall be permanently displayed in the elevator machine room, elevator machinery space, elevator control space, or elevator control room in a conspicuous location with a minimum of 1 1/2" letters on a contrasting background stating, NO COMBUSTIBLE STORAGE PERMITTED IN THIS ROOM By Order of the Fire Marshal (or name of fire authority).

- 21.3.11 Actuation from the elevator hoistway, elevator machine room, elevator machinery space, elevator control space or elevator control room smoke detectors or other automatic fire detection as permitted by 21.3.9 shall cause separate and distinct visible annunciation at the building fire alarm control unit or at the fire alarm control unit described in 21.3.2. Removed the following portion: and at required annunciators to alert firefighters and other emergency personnel that the elevators are no longer safe to use.

- 21.3.13 Separate outputs from the building fire alarm control unit or the fire alarm control unit or the fire alarm control unit described in 21.3.2 to the elevator controller(s) shall be provided to implement elevator Phase 1 Emergency Recall Operation in accordance with Section 2.27 of ANSI/ASME A17.1/CSA B44, Safety Code for Elevators and Escalators, as required in 21.3.13 through 21.3.13.3.

Chapter 21 Changes - Specific to Fire Service Access Elevators

- 21.5 Fire Service Access Elevators. Where one or more elevators are specifically designated and marked as fire service access elevators, 21.5.1 and 21.5.2 shall apply.

- 21.5.1* Status of elevator(s), including location within the hoistway, direction of travel, and whether the elevator(s) are occupied, shall be permitted to be displayed on a building fire alarm system annunciator located at the fire command center.

- 21.5.2 Temperature and presence of smoke in associated lobbies, machine rooms, control rooms, machinery spaces, or control spaces shall be continuously monitored and displayed on a building fire alarm system annunciator located in the fire command center.

- The conditions in 21.5.1 and 21.5.2 shall be permitted to be displayed on a standard emergency services interface complying with Section 18.11.

Chapter 21 Changes - Specific to Door and Shutter Release

- 21.8.3 All door and shutter hold-open release and integral door and shutter release and closure devices used for release service shall be monitored for integrity in accordance with section 12.6. Exception: Pathways installed as Class D circuits in accordance with 12.3.4.