The below diagram is a sample of the fire alarm elevator shunt trip wiring method that is required by NFPA 72. If you would like a copy of this document, please join our Facebook Group HERE and search the documents tab.

The #1 website for NICET Practice Tests, NICET study guides, Fire Alarm Code Knowledge, and General Fire Alarm Topics. We have up to date information on the newest fire alarm trends such as fire service access elevators, mass notification, voice intelligibility, occupant evacuation elevators and two-way communication for Areas of Refuge. Topics also include fire alarm system programming and technical tips. Learn how to build the best ground fault meter with step by step instructions.

Showing posts with label elevator shunt trip. Show all posts

Showing posts with label elevator shunt trip. Show all posts

Tuesday, December 20, 2016

Elevator Shunt Trip Wiring Diagram

Elevator Recall and Shunt Trip Basics

Here are the BASIC Fundamentals of Elevator Recall and Elevator Shunt Trip for Fire Alarm Systems.

- 1st Floor Elevator Lobby Smoke Detector (activates alternate level recall sending the elevator to the second floor) NFPA 72 2016 21.3.13.2

- 2nd Floor Elevator Lobby Smoke Detector (activates designated level recall sending the elevator to the first floor) NFPA 72 2016 21.3.13.1

- Elevator equipment room Smoke (if its on the designated recall level, it should send the elevator to the alternate recall level, if the room is on the alternate recall level, the smoke should send the elevator to the designated recall level)

- Elevator equipment room Heat (Only required if the room is covered by automatic sprinklers) If this is the case, a heat detector shall be mounted within 2 feet of all sprinkler heads (NFPA 72 2016 Edition 21.4.2). This heat detector will activate the elevator shunt trip function causing the elevator power to shut down. Per NFPA 72 2016 the heat detector shall be set at both a higher sensitivity and lower temperature setting than the sprinkler heads. This is so that the elevator power can be shut down before water is released on live (hot) equipment. Note that a time delay must be in place to allow the elevator to travel from the top of the elevator hoistway to the lowest level of recall prior to shutting down the power (see NFPA 72 2016 Edition A.21.4.2)

- Elevator shaft or hoistway. If the top of the elevator hoistway or shaft is equipped with an automatic sprinkler head, you are required to install a smoke detector and a heat detector within 2 feet. The smoke detector will recall the elevator to the first floor and the heat detector will activate the shunt trip as stated above. Note that a time delay must be in place to allow the elevator to travel from the top of the elevator hoistway to the lowest level of recall prior to shutting down the power (see NFPA 72 2016 Edition A.21.4.2). Also note that other methods can be used to achieve shunt trip function with elevators and fire alarm systems. One way is to use a heat as specified above, two is to use a pre-action systems, and three is to use a waterflow/pressure switch. If a waterflow or pressure switch is used for the shunt trip function of an elevator, there shall NOT be a delay (see NFPA 72 2016 Edition 21.4.3). On top of that, the automatic sprinkler pipe branch has to be dedicated with its own ITV (inspectors test valve). More information found here.

- Elevator shaft or hoistway pit. If there is an automatic sprinkler head located in the elevator pit remember this. The head must be located higher than 2 feet off the bottom of the shaft in order to require any special requirements from the fire alarm system. If the sprinkler head is located at 2 feet or lower, nothing is required on the fire alarm side. Here is an article titled "Is a Heat Detector Required in the Elevator Pit".

- Fireman's hat light. You have probably seen it, it is a red light located at the elevator controls depicting the side profile of a fireman's hat. This light needs to be programmed to activate (illuminate) if there is an activation of any fire alarm device in the elevator equipment room and or elevator shaft or hoistway. This is in place to warn first responders that there is a fire in the elevator equipment room and or shaft so DO NOT OPEN! See NFPA 72 2016 edition 21.3.13.3*

Now in today's world we have three different rooms we want to research before we layout the fire alarm devices required for a particular elevator recall system. Below is a breakdown of these three rooms.

- Elevator Machine/Equipment Room: This is the standard room that we see on most projects. This room will house all of the actual elevator equipment, machines, motors, controls etc. In this room, we need to install the necessary relays for recall (primary and alternate as well as a relay for the fireman's hat light, smoke detection to cover the room space and heat detection if the area is is covered/protected by an automatic fire sprinkler system.

- Elevator Control Room: This is a smaller room that houses the controls for the elevators. This room will not contain the actual motors or machinery for the cars themselves. The machinery and equipment will be located within the elevator shaft. With that said, the

- Elevator Closet: This is a panel within the elevator shaft that houses all of the controls for the car's machinery. Like the elevator control room, the closet is a clear indication that the machinery is located in the shaft.

Here is a sample elevator shunt trip wiring diagram article

Saturday, December 17, 2016

How to Wire Elevator Shunt Trip

Elevator Shunt Trip Wiring

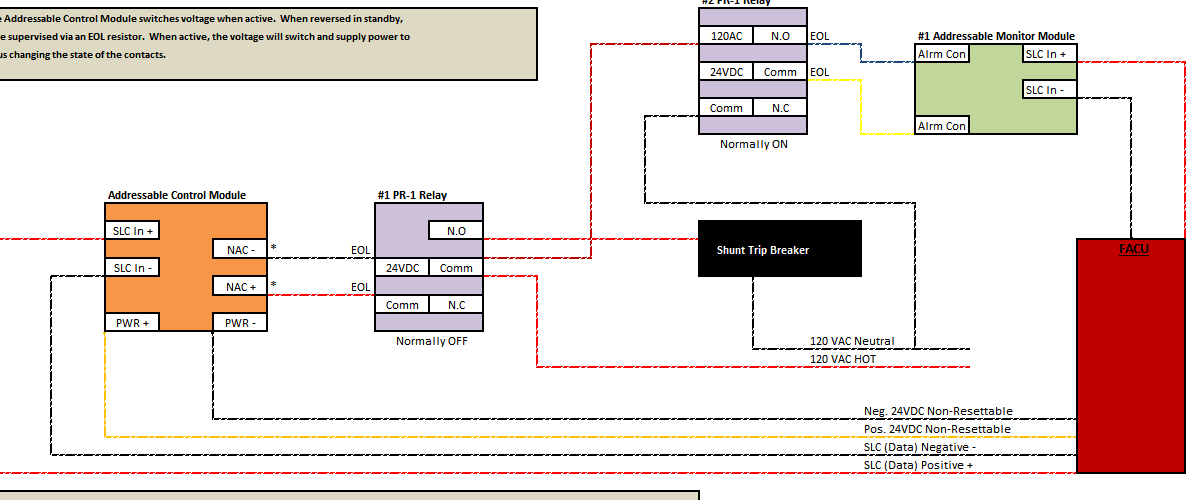

We have created an easy to follow document for the proper wiring method with elevator shunt trip functions. This document includes two methods both based on the supervision requirements of NFPA 72 2016 edition section A.21.4.4.Below is a sample picture of the document that is available for download on our Facebook Group.

It is important to remember that the wiring between the FACP/FACU and the ECID (Emergency Control Interface Device) needs to be supervised. In one method below, we are using an addressable relay module (FRM-1) to operate the shunt trip breaker directly. With this wiring method, only the wire to the FRM-1 (SLC) needs to be supervised. This is obviously achieved through the SLC and addressing of the device.

In the alternate method, we are showing you how to properly wire up the equipment when the load of the circuit exceeds the rating of the FRM-1. In this case you would need to install a PR-1 interface relay (rated for 10 amps). Now that you have a PR-1 switching the shunt trip circuit, this becomes your ECID (Emergency Control Interface Device) and the wiring up to this relay needs to be supervised. To save the cost of an additional addressable monitor module (FMM-1) we can switch out the FRM-1 with a FCM-1 (addressable control module). By doing this, we can achieve supervision as well as activation of the PR-1 interface relay through one device.

Make sure to download the document and let us know your thoughts.

Tuesday, March 24, 2015

Elevator Shunt Trip Requirements and Codes

Elevator Shunt Trip Explained

|

| Elevator Shunt Trip Wiring Detail |

Group II and older elevators DO NOT have shunt trip

Group III and IV DO have shunt trip

Shunt Trip NOT permitted in Fire Service Access Elevators or Occupant Evacuation Elevators.

What Specific Codes or Standards Address Elevator Shunt Trip?

The Fire Alarm and Signaling Code or NFPA 72 2016 section 21.4.2* states the following "If heat detectors are used to shut down elevator power prior to sprinkler operation, they shall be placed within 24 inches of EACH sprinkler head and be installed in accordance with the requirements of Chapter 17. Alternatively, engineering methods, such as those specified in Annex B, shall be permitted to be used to select and place heat detectors to ensure response prior to any sprinkler head operation under a variety of fire growth rate scenarios.".

In order to ensure the elevator shunt trip control relay is activated prior to sprinkler head operation is addressed in NFPA 72 2016 section 21.4.1. "Where heat detectors are used to shut down elevator power prior to sprinkler operation, the heat detector shall have both a lower temperature rating and a higher sensitivity compared to the sprinkler."

ASME A17.1 2013 "In jurisdictions not enforcing the NBCC, where elevator equipment is located or its enclosure is configured such that application of water from sprinklers could cause unsafe elevator operation, means shall be provided to automatically disconnect the main power supply to the affected elevator and any other power supplies used to move the elevator upon or prior to the application of water. This means shall be independent of the elevator control and shall NOT be self-resetting."

Basically if there is potential for automatic fire sprinkler water to make its way onto the elevator controls or other power supplies for the elevator, there needs to be a way to shut down prior to this event.

Here are some "UNSAFE" conditions that can be caused by the automatic sprinkler system operation:

- Elevator may react erratically due to water shorting out controls

- Water on the elevator braking system

- Risk of Shock or Electrocution

Also note that NFPA 13 and the International Building Code address when and where sprinklers will be used for elevator spaces. In basic terms, sprinklers are not permitted in elevator spaces if the materials in these spaces are not combustible. However, if there are combustible hydraulic fluid, coated belts, controls, etc. then sprinklers will be provided. Just remember, No Sprinklers, No Shunt Trip.

We constantly get asked if you are required to install a heat detector in the bottom of the elevator shaft or elevator pit. For more information on this topic, review our article titled "Is a Heat Detector Required in the Elevator Pit?"

We constantly get asked if you are required to install a heat detector in the bottom of the elevator shaft or elevator pit. For more information on this topic, review our article titled "Is a Heat Detector Required in the Elevator Pit?"

Can the Elevator Shunt Trip Activation be Delayed?

The answer is YES. The activation of heat detectors can delay the elevator shunt trip via programming for a delay time not to exceed the time it takes the elevator cab starting at the top level to reach the lowest level of exit discharge. The purpose behind this allowance is to increase the potential for elevators to complete their travel to the recall level. Make note that the requirements of A17.1/B44 Safety Code for Elevators and Escalators would still apply.

If your fire alarm system utilizes waterflow or pressure switches to activate the elevator shunt trip, any time delay switches or capability will NOT be permitted per NFPA 72 2016 section 21.4.3.

Shunt Trip Control Circuits to be Monitored for Operating Voltage

This is a step that seems to be missed a lot. NFPA 72 2016 section 21.4.4 mentions that the control circuits used to shut down power to the elevator shall be monitored for the presence of operating voltage. If the voltage is not present than a supervisory signal shall be indicated at the fire alarm control unit.

This activation can easily be accomplished with a PR-1 relay and addressable monitor module. Power the PR-1 with the shunt trip control circuit and connect your addressable monitor module to the Common and Normally Open leads. If the Control circuit loses power, the PR-1 will change state and short your IDC on the monitor module. Program the module for tracking supervisory and label it "Shunt Trip Power".

What is the Requirement for Shunt Trip Breaker Location?

As of now, National Codes/Standard and Elevator Codes DO NOT indicate specific locations for the elevator shunt trip breaker. However, in California the elevator shunt trip breaker must be installed OUTSIDE the elevator machine room (EMR). The thought behind this is once the circuit is shunted, sprinkler activation can drip water over the breaker and return power to the elevator.

Resetting a Shunt Trip Breaker

When the shunt trip breaker is activated, the breaker switch itself will be between on and off. To reset the breaker, make sure the controlling fire alarm system is reset and back to normal. Once the FACU is reset, flip the shunt trip breaker all the way towards the off position (should be some tension) and then flick it all the way back to on.

Thursday, March 19, 2015

Is a Heat Detector Required for the Elevator Pit

Designers are always asking, "Do I need to put a heat detector in the elevator pit?"

"Are you required to install a heat detector in the bottom of the elevator shaft otherwise known as the elevator pit?". This is a question that comes up a lot in the fire alarm industry and often has system designers and AHJs (Authority Having Jurisdiction) scratching their heads. Another related questions is, "Why is there a sprinkler head located at the bottom of the elevator shaft?". A sprinkler head located in the bottom of the elevator pit is in place to control the spread of fire caused by the ignition of trash and debris that has fallen through the door opening and collected over time. There are two items that need to be present before the requirement of a fire alarm system heat detector is required. One is the presence of an automatic sprinkler head. NFPA 13 2010 ed. 8.15.5 states that sprinklers heads are to be installed in the top and bottom of the elevator shaft. There are exceptions to this rule so keep in mind that not all elevator shafts will incorporate a sprinkler head. Two is the height in which the sprinkler head is installed off the floor of the elevator pit. ASME A17.1 states that if a sprinkler head is installed within 24" (2 feet) of the elevator pit floor, it shall be exempt from the special arrangements of inhibiting water flow until the elevator recall function has occurred.

There are two items that need to be present before the requirement of a fire alarm system heat detector is required. One is the presence of an automatic sprinkler head. NFPA 13 2010 ed. 8.15.5 states that sprinklers heads are to be installed in the top and bottom of the elevator shaft. There are exceptions to this rule so keep in mind that not all elevator shafts will incorporate a sprinkler head. Two is the height in which the sprinkler head is installed off the floor of the elevator pit. ASME A17.1 states that if a sprinkler head is installed within 24" (2 feet) of the elevator pit floor, it shall be exempt from the special arrangements of inhibiting water flow until the elevator recall function has occurred.A heat detector is required to be installed within 2' of any sprinkler head associated with shutting down the power to an elevator (NFPA 72 2016 ed. 21.4.2*). It is important to shut down the elevator power prior to the release of water from a sprinkler head since water and electronics do not mix. This is the reason the heat detector is required to be set to a lower temperature setting and higher sensitivity setting than the sprinkler head (NFPA 72 2016 ed 21.4.1*). With that said, a heat detector is not required if the sprinkler head is located within 24" of the elevator pit floor since there is typically not any electrical components located in this area.

There are three common methods to shutting down the main elevator power prior to water flowing from a sprinkler head in the shaft or elevator machine room.

#1) The most economical method is to use a waterflow switch. Upon activation, the waterflow switch would cause an alarm at the FACU (Fire Alarm Control Unit) as well as activate the shunt trip breaker causing the power to be interrupted. Make sure you follow NFPA 72 2010 ed 21.4.3*. This code section states that if using waterflow or pressure switches to shut down elevator power, the use of a time delay shall not be permitted.

#2) This is the most common method. By use of a fixed temperature rate of rise heat detector located within 2' of each sprinkler head in the shaft, hoistway or elevator machine room. The heat detector shall be set to a lower temperature than the sprinkler head and when activated, will cause an alarm at the FACU and shunt the breaker associated with powering the elevator.

#3) Use of a pre-action system. These systems would have supplemental fire detection devices installed in the same areas as the sprinkler heads. Make note that the detection devices should be heat detectors. Once on of the heat detectors have been activated, it would tell the pre-action control panel through program mapping to open a valve control by a solenoid. Once the valve is open, water would then fill the sprinkler system piping in the elevator hoistway and elevator equipment room. At the same time, the heat detector would also trip the shunt breaker thus shutting down the elevator power. If a fire really is present in these areas, it would eventually fuse the sprinkler head and release water to the affected area.

Keep in mind that heat detectors are to be used for shutting down power to the elevator and not smoke detectors. Smoke detectors associated with elevators are to be solely used for designated elevator recall, alternate elevator recall and to activate the elevator hoistway smoke relief equipment.

Saturday, May 18, 2013

Elevator Recall Explanation and Programming

Elevator Recall Programming for Fire Alarm

Programming and designing elevator recall for fire alarm systems is a fairly simple process if you are familiar with the codes and standards in place. Most fire alarm programmers and contractors understand the principle behind capturing passenger elevators but for those of you that don't, check this out!

Per NFPA 72 2016 section 21.3.1, elevators are required by code to be connected and controlled by a Building Fire Alarm System (NFPA 72 2016 3.3.103.4.1) or an Elevator Recall System which falls under the NFPA 72 classification of Dedicated Function Fire Alarm System (NFPA 72 2016 3.3.103.4.2).

As required by NFPA 72 2016 21.3.5*, the spot type smoke detectors for the use of capturing the passenger elevator shall be mounted within 21' center line of the elevator door. In addition to these detectors, you will have smoke detector(s) in the elevator machine (EMR) room and at the top of the elevator hoistway. Keep in mind that smoke detection in the elevator shaft is only required if the elevator hoistway has automatic sprinklers. Automatic sprinklers are only found in the elevator hoistway if the elevator is constructed of combustible material. Consult NFPA 13 and the International Building Code for more details. All of these spot type smoke detectors will be associated with your building fire alarm or dedicated function elevator system's elevator recall functions.

Regarding the elevator and the building fire alarm system relationship, we have additional functions that require the installation of thermal spot type heat detectors. You will need these thermal spot type heat detectors in the elevator machine room (EMR) and elevator shaft (only if automatic sprinklers are present). Note these heat detectors do not recall or capture the elevators. These thermal heat detectors shunt the power to the elevator controller in the event of a fire. Remember the thermal spot type detectors used for shunt trip are required to be set or programmed to a lower temperature point then the surrounding automatic sprinkler heads. The intent is for the fire alarm system to sense the fire before the automatic sprinkler heads. This way the fire alarm control unit (FACU) can disconnect the power to the elevator controls prior to the sprinkler head applying water to its electronics. You can read more about fire alarm system elevator shunt trip in the following article: elevator shunt trip.

Designated Level Recall and Alternate Level Recall

NFPA 72 2016 21.3.13.1. Designated Level Recall. All smoke detectors associated with elevator recall that are not installed on the primary floor of egress including the top of the elevator shaft will activate the designated level elevator recall relay. This function will send the elevator car to the main level of exit discharge. (typically lobby floor or level #1 depending on the building layout).

NFPA 72 2016 21.3.13.2. Alternate Level Recall. All smoke detectors associated with elevator recall that are installed on the main level of exit discharge will activate the alternate level elevator recall relay. This function will send the passenger elevator to the alternate floor of egress. (typically the basement or 2nd floor depending on the building layout).

The floor or level where the elevator equipment room is located will determine the recall relay to be activated in the event of an activated smoke detector. Example: If the elevator machine room (EMR) is located on the first floor, its associated smoke will activate the alternate elevator recall relay. If the elevator machine room is located on the roof, its associated smoke detector will activate the designated elevator recall relay.

The floor or level where the elevator equipment room is located will determine the recall relay to be activated in the event of an activated smoke detector. Example: If the elevator machine room (EMR) is located on the first floor, its associated smoke will activate the alternate elevator recall relay. If the elevator machine room is located on the roof, its associated smoke detector will activate the designated elevator recall relay.The heat detectors in the elevator machine room and elevator hoistway will activate the shunt trip relay killing power to the controller. On top of this the heat detectors shall shut off any back-up power to the elevator. Per NFPA 72 2016 section 21.3.13.3* The elevator hoistway and equipment machine room smoke detectors and or heat detectors shall activate a visual warning commonly known as the flashing Fireman's Hat Light near the elevator call buttons. This allows the fire department to become aware if there is a fire in the hoistway or elevator machine room.

Now programming all of this might seem difficult but it is actually really simple. Get basic instructions on how the programming breaks down in this article: fire alarm system with elevator recall.

Make sure to join our Fire Alarms Online Facebook Group HERE.

Subscribe to:

Posts (Atom)