2 hour CI Cable and Survivability

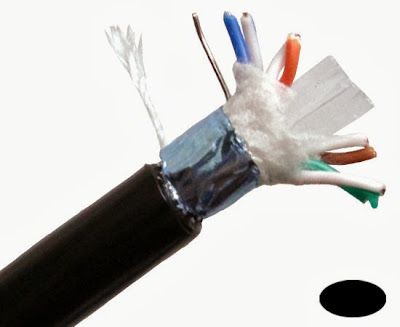

As you may already know, UL (Underwriters Laboratories) has pulled their listing on 2-hour rated circuit integrity (CI) cable. Since this cable technically no longer exists, what are we to do in current and future installations requiring the use of this CI cable? According to the UL document, it is now up to the discretion of the local AHJ as to when it can be used or substituted with an alternate means of media.Now, where did the 2-hour rating come from? It is my understanding that stairwells are required to be 2-hour rated in buildings over four stories in height. With buildings that are four stories and under in size, you will typically have a general alarm sequence and won't require any Pathway Survivability. Buildings over four stories start getting close to the threshold for a high rise building where pathway survivability defiantly plays a role. Depending on the level of Pathway Survivability (see NFPA 72 2010 section 12.4) level 0, 1, 2, or 3 you will have to protect your circuit pathway for a period of two hours. Now this can be accomplished by either installing 2-hour rated cable or CI cable, 2-hour rated cable system [electrical circuit protective system(s)], 2-hour rated enclosure or protected area, or 2-hour performance alternatives approved by the authority having jurisdiction (AHJ). Note that level 0 has no requirement for pathway survivability and level 1 can be accomplished if the building is fully protected by an automatic sprinkler system.

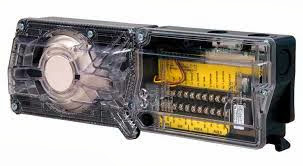

To make it simple, you can run your cables for a fire fighters telephone circuit up a 2-hour rated stairwell without the use of CI cable. However, when you exit the stairwell to extend the circuit to other areas of the building, you need to use 2-hour rated CI cable. The intent in my mind is to provide a complete circuit pathway from the fire alarm control unit FACU to the field devices with a rating of not less than 2 hours.

Alright, so the concept is clear, you want to provide a fire alarm system that is capable of lasting at a minimum, 2 hours in the event of a fire. This allows time for all of the occupants to evacuate and remain clear of the building. After all it is the ultimate goal of a fire alarm, voice evacuation or mass notification system to notify the occupants of the emergency at hand. If the wiring fails then obviously you no longer have the ability to broadcast out to your field notification appliances. Now this is where it gets crazy. The FACU or Fire Alarm Control Unit is not required to be 2-hour rated nor are the field devices such as fire fighter's telephone jacks, speakers, strobes, horns, etc. So how is it that we have codes in place to insure that our fire alarm circuit pathways are secure for a period of 2 hours but not the control or notification equipment. If there is a fire in a high rise that lasts 2 hours, the field devices would not stand a chance. So what do we have when the fire is all said and done? A voice evacuation system with operational cables but nothing to activate, control or notify.

I am not sure as to why UL pulled their listing on CI cable but I honestly am not up in arms about it. UL is remaining very silent on the issue and will not disclose any information regarding the test results of CI cables. At this time, to save your customer money and your technicians the hassle I recommend bringing this topic up with your local AHJ and finding out if he/she will allow the use of other cables in applications requiring NFPA 72 Pathway Survivability Levels 2 or 3.

If you are interested in taking the NICET CBT exam for fire alarms, then we have you covered! We are now selling our CBT Levels 1 - 3 practice exam DVDs. These DVDs are packed with tons of NICET CBT practice exams along with all code references as to where to find the answers. We have also supplied the DVDs with all of the necessary NICET applications, CBT calculator demonstrations, links and more. If you need more information, feel free to send an email. You can find the link to purchase our DVDs on the top left section of each page on this site.

.jpg)